- Prefabrication and modular construction improve efficiency, reduce waste, and enhance quality control in construction projects.

- 3D printing can significantly reduce construction time, cost, provide design flexibility, and promote sustainability.

- Building Information Modeling (BIM) is a digital tool that enhances collaboration, accuracy, and efficiency in construction projects.

- Autonomous construction equipment can increase productivity and safety on construction sites.

- The industry is shifting towards sustainability through eco-friendly practices, such as wire rope sling capacities.

The construction industry constantly evolves, driven by technological advancements and a growing need for efficiency, sustainability, and safety. To stay competitive and meet the demands of modern construction projects, professionals in the field have been adopting innovative techniques and technologies. This guide will explore five groundbreaking techniques that are transforming the construction industry.

1. Prefabrication and Modular Construction

Prefabrication and modular construction have emerged as game-changing techniques in the construction industry. Prefabrication involves assembling components in a controlled factory environment, such as walls, floors, and entire rooms. These components are then transported to the construction site and assembled, reducing construction time and minimizing on-site disruptions.

Modular construction takes prefabrication a step further by creating entire building modules manufactured off-site and transported, stacked, or connected at the construction site. This approach is particularly popular in residential buildings, hotels, and student housing construction. Both techniques improve efficiency, reduce waste, and enhance quality control, making construction projects more cost-effective and sustainable.

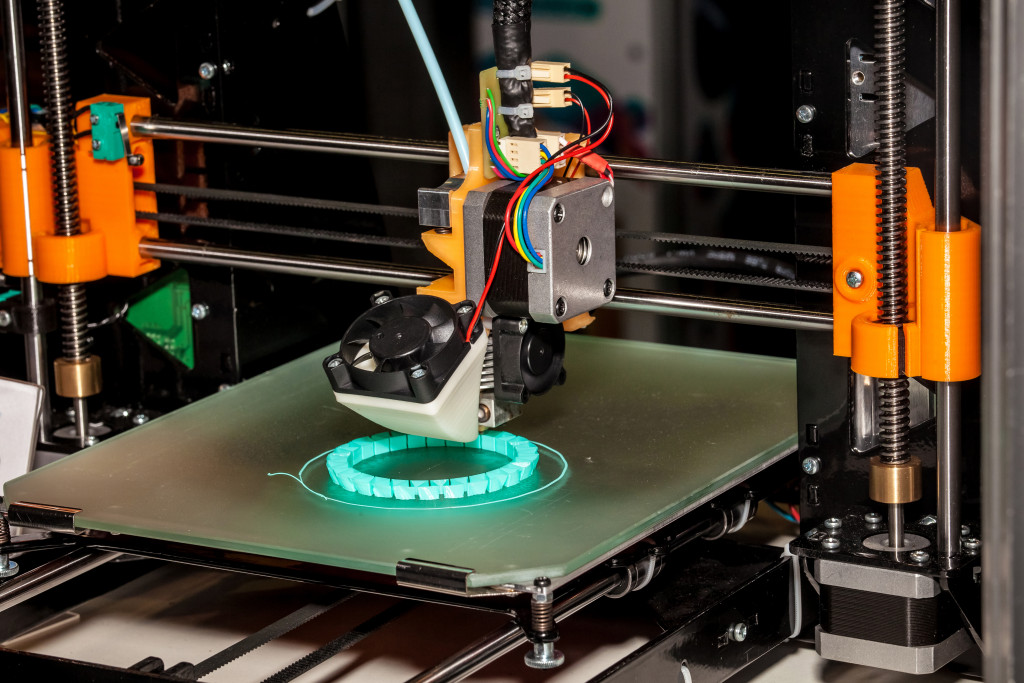

2. 3D Printing

3D printing, once a technology mainly associated with manufacturing, has found its way into construction.

Here are the benefits of 3D printing:

Reduced Construction Time

3D printing can significantly reduce construction time compared to traditional methods. The use of automated machines eliminates many manual labor processes, making it possible to construct buildings at a faster pace. This is especially beneficial for large-scale projects that require repeated and precise manufacturing of components.

Furthermore, 3D printing can manufacture entire structures in one go rather than assembling individual pieces on-site. This reduces the overall construction time and allows for quicker building occupancy.

Cost Savings

With 3D printing, there is a potential for significant cost savings in the construction industry. As mentioned, it reduces labor costs by automating many processes and eliminating the need for skilled workers to perform manual tasks. Additionally, 3D printing can reduce material waste by only using the necessary construction material to build a structure.

Moreover, logistical challenges can make constructing buildings in remote areas or disaster-stricken regions expensive. With 3D printing, the technology can be transported and set up on-site, reducing transportation costs and providing more cost-effective solutions for housing needs.

Design Flexibility

3D printing allows for more design flexibility and customization in construction. Since the structures are built layer by layer, intricate designs and complex geometries can be achieved with precision. This gives architects and engineers more creative freedom to explore new shapes and forms previously difficult or impossible to construct.

Furthermore, 3D printing can easily incorporate sustainability features into the design, such as creating hollow structures that allow for natural ventilation and reduce energy consumption.

Sustainability

The use of 3D printing in construction also has positive implications for sustainability. As mentioned, it can reduce material waste and incorporate sustainable features into the design. Additionally, 3D printing can use recycled or bio-based materials, making it a more environmentally friendly option for construction.

Furthermore, 3D printing can also reduce construction’s carbon footprint by minimizing transportation and on-site construction activities. This has the potential to decrease greenhouse gas emissions in the industry significantly.

3. Building Information Modeling (BIM)

Building Information Modeling or BIM serves as a comprehensive digital depiction of a building’s physical attributes and functional characteristics. It’s a powerful tool that allows construction professionals to plan, design, and manage projects in a collaborative and data-driven manner. BIM integrates 3D modeling, project scheduling, cost estimation, and other critical aspects of construction.

With BIM, stakeholders can visualize the entire construction process before it begins, identifying potential clashes or issues that can be resolved in the planning phase. This results in fewer changes during construction, reducing delays and cost overruns. Additionally, BIM enhances communication and collaboration among project teams, from architects and engineers to contractors and subcontractors. It’s a technology-driven approach that improves project efficiency and accuracy, ultimately delivering better buildings.

4. Autonomous Construction Equipment

The construction industry embraces autonomous construction equipment that can operate without human intervention. These machines, equipped with advanced sensors, GPS technology, and artificial intelligence, can perform excavation, grading, and bricklaying with precision and efficiency.

Autonomous equipment increases productivity and improves safety by reducing the need for workers to perform hazardous tasks. These machines can work around the clock in various weather conditions and are programmed to avoid obstacles and adjust to environmental changes. While the initial investment in autonomous construction equipment can be high, the long-term cost savings and enhanced project timelines make it a compelling choice for many construction companies.

5. Sustainability and Eco-Friendly Practices

Sustainability has become a central focus in the construction industry. Innovative techniques and materials are being used to reduce the environmental impact of construction projects. From green building certifications like LEED (Leadership in Energy and Environmental Design) to using recycled and renewable materials, construction professionals actively seek ways to make their projects more eco-friendly.

One notable aspect of sustainability in construction is using reliable wire rope sling capacities. These versatile and durable slings are made from high-strength steel cables and are commonly used for lifting and hoisting heavy materials on construction sites. Their ability to be reused multiple times makes them innovative in sustainability, reducing the need for disposable lifting equipment. Construction companies can improve safety and efficiency by using wire rope sling capacities and contribute to a more sustainable construction industry.

In Closing

The construction industry is amid a technological revolution, and these innovative techniques are shaping how we build. These advancements, from prefabrication and 3D printing to BIM and autonomous equipment, increase construction projects’ efficiency, safety, and sustainability. As the industry continues to evolve, staying informed about these cutting-edge techniques is crucial for professionals looking to thrive in this dynamic field. Embracing innovation is a key to success and a way to build a better, more sustainable future.